Slip resistant

Invisible fixing

Easy to maintain

Available colours

Duofuse composite decking is available in 4 attractive shades. After several days, the Duofuse boards will begin to discolour. This is a natural and temporary process. After a few weeks/months, the original colour of the panels will be regained.

Graphite Black

Stone Grey

Tropical Brown

Wenge Brown

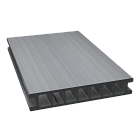

DFD162

Hollow decking board

The DFD162 decking boards can be used on both sides.

One side has a fine grooved texture, the other side is a wide grooved texture.

Length: 4000 mm

Width: 162 mm

Thickness: 28 mm

Fine grooved texture

Wide grooved texture

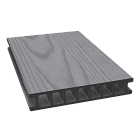

DFDE162

Hollow decking board

The DFDE162 decking boards can be used on both sides.

One side has a brushed texture, the other side has a woodgrain texture. Over time, natural wear and exposure will gradually soften the appearance of the wood grain.

Length: 4000 mm

Width: 162 mm

Thickness: 28 mm

Brushed texture

Woodgrain texture

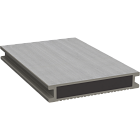

DFDS162

Massive decking board

The DFDS162 is a unique product. It's sollid, yet surprisingly lightweight thanks to its specially designed core. These decking boards can be used on both sides.

One side has a fine grooved texture, the other side has a brushed texture.

Length: 4000 mm

Width: 162 mm

Thickness: 28 mm

Brushed texture

Fine grooved texture

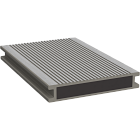

DFDE140

Massive decking board

The DFDE140 is the heavy duty board of Duofuse. With its 140mm width it's smaller than the other type of Duofuse decking boards. One side has a fine grooved texture, the other side has a woodgrain texture.

Length: 4000 mm

Width: 140 mm

Thickness: 28 mm

Fine grooved texture

Woodgrain texture

Substructure

The components required for installing a deck depend on the type of surface it will be built on and the type of beam selected. There are two main installation types: on a solid surface or as a floating structure, such as on a rooftop terrace. Below is an overview of the different types of beams and the corresponding components needed for each installation method.

Solid surface

A solid surface refers to a stable and permanent base onto which the deck structure can be directly mounted. Examples include a concrete slab or paved patio. In this setup, the beams are securely anchored to the solid surface using appropriate fasteners such as plugs and screws. This creates a strong and reliable foundation for the decking boards.

The components listed below are suitable for the installation of a terrace using aluminium support beams.

Floating structure

A floating structure is used when there is a solid surface with a height difference that cannot be corrected using the beams alone, or when the surface cannot be altered by anchoring the beams directly onto it. In this case, a sturdy frame of aluminum beams is constructed and placed on adjustable pedestals.

For higher placements or placement on roof terraces you can use polypropylene pedestals that allow heights of more than 200 mm. When using these pedestals, however, you cannot use wood composite beams, since it is not a structural element.

The components listed below are suitable for the installation of a terrace using Aluminium support beams.

To finish the terrace, a finishing skirting board can be used.

This skirting board is available in both wood composite and aluminum, allowing you to choose the option that best matches your aesthetic preferences and durability needs. It can be used in combination with a terrace installation on wood, PVC, or aluminum support beams.

Installing a finishing skirting board not only enhances the overall appearance of the terrace by covering the edges, but also helps protect the structure and maintain a clean, professional look.

Fire certification

The need for fire-certified products is increasing and depends heavily on the situation. For a patio in a traditional garden, there are generally no requirements, although it is certainly advantageous that materials don't immediately ignite when used with things like a barbecue or fire pit. For emergency escape applications, patio planks must meet at least Cfl classification.

All colors within the DFD, DFDE, and DFDS types have been individually tested for their fire behavior, because color actually influences performance when exposed to fire.

Fire certification is never issued solely for the product itself, but always depends on the entire structure in which it is used. Therefore, fire certification is only valid when the patio plank is used in combination with the aluminum substructure.

| Fire reaction when using aluminium substructure | EN 13501-1 | (zie onder) | - | |

| Graphite Black | Stone Grey | Tropical Brown | Wenge Brown | |

|---|---|---|---|---|

| DFD140 | BFL - s1 | BFL - s1 | BFL - s1 | BFL - s1 |

| DFD162 | DFL - s2 | DFL - s2 | CFL - s1 | CFL - s1 |

| DFDE162 | DFL - s2 | DFL - s2 | CFL - s1 | CFL - s1 |

| DFDS162 | DFL - s2 | DFL - s2 | BFL - s1 |

BFL - s1 |

Why Duofuse?

Inspiration

Decking boards configurator

Calculate the number of Duofuse components you need for your decking with our online configurator

0117 300 5625

0117 300 5625